Thought I'd share something I learned when I started in on my closed head drum.

I used a jigsaw to cut the top off. Easy, and quick. I cut right against the edge.

Then I got my angle grinder out to smooth the inside edge. My weber top was slightly too small to fit the drum, so I started in shaving down the lip. Around and around a few times, checking the fit as I went, and suddenly the part of the lip cut from the lid came loose and I lifted it right off the drum, leaving only the drum wall lip there. A little more grinding and the webber fit like a glove.

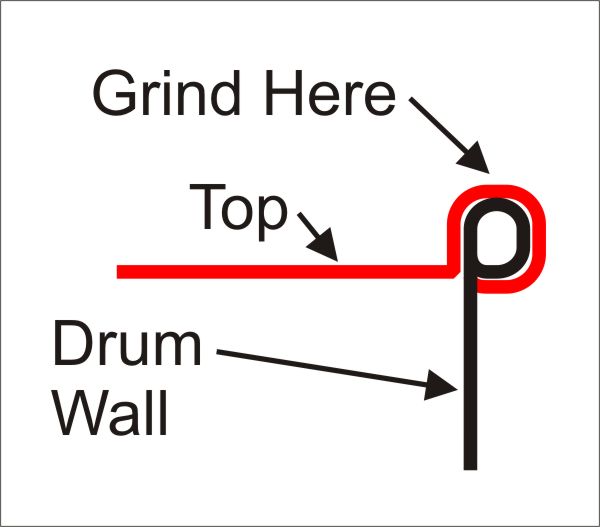

I didn't think much of this until I went to help my friend Adam open up his closed head drum a couple days ago. We were discussing how this lip came off and decided to skip cutting the top off and try to do it by just grinding the very top edge of the drum until we were just through the lids rolled edge. Sure enough, with very little effort, doing this easily separated the lid from the drum and made sizing it to his webber lid easy as well.

Here's a quick drawing I made of the way the drum wall is rolled and then the lid is rolled over that drum wall lip.

And here's a quick youtube video I made of Adam grinding the top edge, and how easy the lid separates.

http://youtu.be/OeaER0yLiK4

I did another drum like this yesterday for another friend, and his was made from thicker metal, but it still separated mighty easy.